The intelligent trend of valve industry is obvious

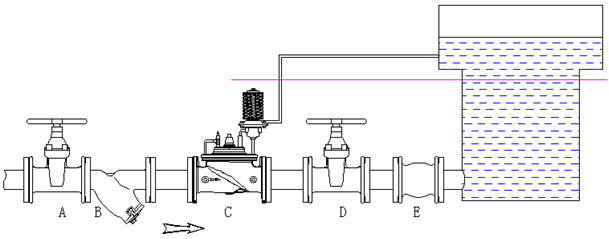

Knife gate valves are commonly used in mining and excavation of precious metal deposits, power supply system of power plants, papermaking production system, chemical material system and food inspection system. Due to the linear movement of the closing baffle (a plate that forms a resistance in the closed position to prevent fluid flow), the knife gate valve has the advantage of being very compact and very sealed. Knife gate valve is mainly composed of a stop valve, edge system and structural system. Although when the valve is in the partially open position, it can also be used as a control valve and well control the flow of fluid.

In addition to being used in the above environment, knife gate valve can also be used in fluids with solid particles, such as common wastewater or sludge cleaning systems. Generally, in order to meet the actual application requirements, the knife gate valve is usually designed to be sealed on the upstream side of the circuit (i.e. the fluid inlet side), but some valves go the opposite way and are sealed on both sides. Therefore, the knife gate valve can be used to achieve the purpose of flow control under any working condition and environment and fluid flow direction. In the open position, the head loss of the valve is very low because the valve will not cause a change in fluid direction. However, the closing and opening time may be very long, so the valve needs regular maintenance to correct the wear between the valve and the seal, which can also prolong the service life of the valve.

View details >>

EN

EN